High Quality Automatic Steel Roofing Cold Roll Forming Machine

Basic Info

Model No.: HKY-roll forming machine

Product Description

Model NO.: HKY-roll forming machine

Certification: ISO9001: 2000, Ce, SGS

Usage: Roof, Wall

Voltage: 380V

Type: Roll Forming Machine

Specification: 9.2*1.5*1.4M

HS Code: 845522

Tile Type: Colored Steel

Condition: New

Transmission Method: Electric

Thickness Range: 0.2mm-1.0mm

Trademark: HKY

Origin: China

Steel roofing cold roll forming machine

Other name: cold roll forming machine, steel roofing roll forming machine.

Components of whole line of steell roofing cold roll forming machine:

1. De-coiler

2. Shearing Device

3. Forming System

4. Cutting device

5. Run-out Table

6. Electrical Sytem

Technological Parameters:

1. Hydraulic Un-coiler

Width of raw material: 1250mm

Max Capacity: 10000kgs

Max out diameter of coil: 1600mm

Inner diameter of coil: 500-600mm

Hydraulic feed and brake

The power of motor: 5.5kw

2. Shearing Device

Shearing way: Manual

The material of blade: Cr12 with Heat treatment HRC60-62

3. Main Forming System

Feeding width: 1219mm

Product width: 1000mm

Height of waves: 37mm

Thickness of sheet: 0.35-0.6mm

Material: GI sheet coil or Colored sheet coil

Roller stations: 18 rows

Material of Roller: C45 steel

Surface of Roller: Chrome plating

Diameter of main shaft: 80mm C45steel, modulation

Main Bearings: 60211

Power of main motor: 5.5kw Servo motor

Forming Speed: 0-15m/min

4. Cutting device

Oil pump station 1set

Motor power of Oil pump station: 4kw

Forced air cooling device available

Cutting mould: 1set

Material of blade: CR12 with heat treatment HRC60-62

Pressure of cutting: 15tons

5. Run-out Table

Frame: Angle bar or steel tube welded

Length: 3m

Quantity: 1 pc

6. Electrical System

PLC and HMI touch Screen

Automatic length measurement

Automatic quantity measurement

Length measurement: Rotary Encoder

Over current protection for control system, aviation plugs

Cutting off type: Paused to cut, moving automatically after cutting.

Power: 440V 60Hz

We also can design and manufacture as per your request!

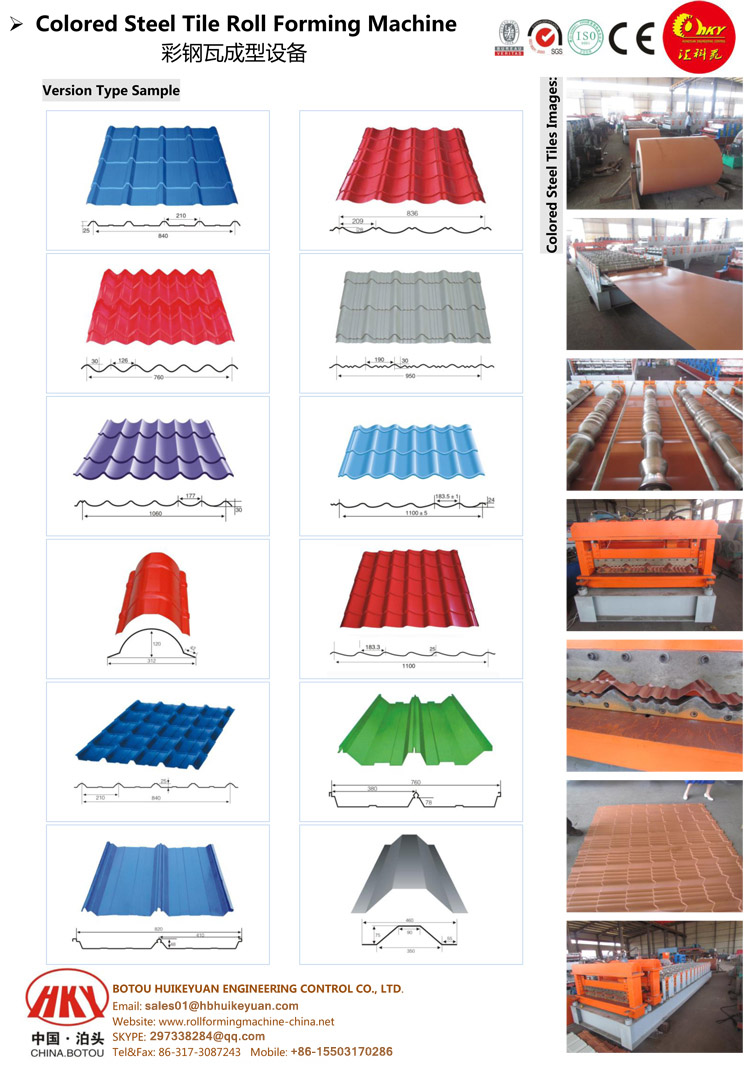

Machine Photos:

Contace Person: Jacky (sales manager)

Mobile: +86-15503170286

| Advantage of our roll forming machine |

| High quality |

| Lower cost |

| Durableness |

| High efficiency |

| Reliable working |

| Low failure rate |

| Low energy consumption |

| Trouble free after sales service |

Contact us if you need more details on Cold Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Roofing Cold Roll Forming Machine、Steel Roofing Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Roof & Wall Roll Forming Machine

Premium Related Products

Other Products

Hot Products

Double Layer Cold Pressure Tile Machine for Glazed and Dovetail PanelsHigh Speed Metal Stud Roll Forming MachinePLC Control Crest Tile Roll Forming MachineAluminum Composite Panel Production LineHydraulic Steel Roof Panel Roll Forming Machinery (HKY)Shutters Door Roll Forming Machine (HKY-J)Good Quality PLC Control Glazed Tile Forming MachineSteel Sandwich Panel Production LineHydraulic Bending Machine, Bending MachineHigh Quality PLC Control C Purlin Forming MachineHky-688 Deck Roll Forming MachineHigh Quality Large Capacity Automatic Hydraulic DecoilerAutomatic Highway Guardrail Roll Forming MachineAutomatic Band Sawing MachineRoll Forming Machinery Making Panel (HKY)PLC Automatic Arched Roof Panel Curving Machine